Experience the Xtreme Difference

Imagine a company that puts their customers’ feedback into action to meet their needs, where safety comes before cost, service comes before sales, and reliability and reputation come before profits. Doing business differently made Xtreme Manufacturing instantly distinguishable and respected within the industry in 2003 with a customer-focused and reputation-first perspective.

Today, Xtreme Manufacturing offers the largest product line of rough terrain telescopic handlers (telehandlers) in North America. Spanning 24 models, with lifting capacities ranging from 5,900 lbs. (2,676kg) to 100,000 lbs (45359kg) , and maximum lift heights of up to 100 ft (30.5m). Xtreme Manufacturing has a telehandler suited to virtually any application and environment.

When Experience Meets Innovation

Dissatisfied with the telehandlers available in 2003, Xtreme Manufacturing owner Don Ahern set about creating his own telehandler which would deliver outstanding performance, using high quality, reliable components to increase the life of the machine and ultimately reduce the total cost of ownership.

The use of long-lasting boom rollers, rather than wear pads, on Xtreme telehandlers for smooth, precise boom operation, improved operator confidence and low maintenance, is one of many features that make the “Xtreme Difference”. Other standard features include 360° operator visibility from the cab, intuitive controls that allow the operator to keep one hand on the steering wheel at all times, and an integrated boom lift point that can lift the maximum rated load of the machine.

Resetting the Standard

Xtreme Manufacturing’s vision to produce the most versatile range of long-lasting and superior products has quickly become the industry standard in performance, innovation, safety, quality, and reliability. With all products built in North America and backed by an industry-leading 10 year – 5 year – 2 year warranty, Xtreme stands firmly behind the quality of their products.

Thinking Inside the Box

Drawing on experience in the construction and industrial sectors, Xtreme used their engineering skills to develop Xtreme Cubes, a portable yet robust modular building solution, that can be customized to suit a variety of applications. From office and retail complexes to maintenance facilities, workforce accommodations, modern residential homes, quick serve restaurants, trade show booths, and many more permanent or temporary turnkey solutions; Xtreme Cubes are the low maintenance, quick-install alternative to traditional buildings and modular constructions.

* Contact an Xtreme sales representative for details and current availability.

HISTORY

Click the plus sign to view our complete history

Founded in 2003, Xtreme Manufacturing has grown to become one of the leading manufacturers of telehandlers in North America, with an increasing global customer base.

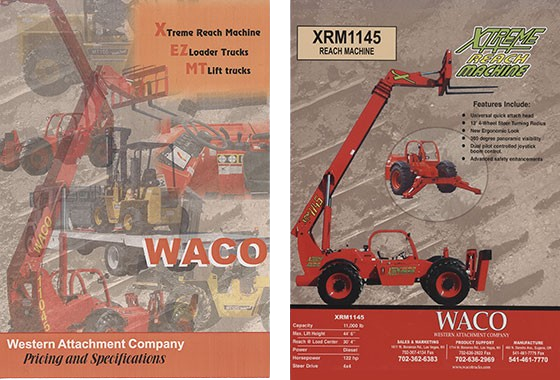

Xtreme Manufacturing was born from Don Ahern’s personal experience in the rental industry, struggling to find a reliable telehandler for his fleet. Inspired to produce his own machine that overcame common engineering faults of products available at the time, Don purchased Western Attachments Company in 1999, an Oregon based forklift company that specialized in rough terrain vertical mast forklifts. This business went on to become Xtreme Manufacturing in 2003, which today produces one of the largest and most versatile ranges of telehandlers in North America.

Additionally, Don harnessed the experience of the Xtreme engineering and manufacturing teams, along with feedback from customers, to fill a void in the market with the development of the Xtreme Cubes™ portable building solution, as well as the E-Z Loader custom-built truck bed designed to reduce the loading and unloading time of equipment deliveries.

1999

Don Ahern purchased Western Attachments Company, an Oregon based forklift company that specialized in creating rough terrain vertical mast forklifts. Don was not satisfied with their product, and set up the Fresno Engineering Group to redesign their products.

2003

In January 2003, Don rebranded Western Attachments Co. as Xtreme Manufacturing. At this time, the first Xtreme telehandler, the XRM945, was developed by the Fresno Engineering group, with a capacity of 9,000 lbs. (4,082kg) and a reach of 45 ft. (13.7m). Due to anticipated growth, Xtreme was relocated from Oregon to Las Vegas, Nevada.

2004

-

2005

During 2004, Xtreme developed five new telehandlers and upgraded two models for increased versatility and higher reach. The Fresno Engineering team was also relocated to Las Vegas, Nevada.

2009

-

2010

Five new telehandlers were added, bringing the Xtreme product line count up to 10 telehandlers ranging from 6,000 lbs. (2721kg) to 30,000 lbs. (13608kg) capacity with up to 67 ft. (20.4m) maximum reach. In 2010, Don sketched the first concept of an Xtreme Cube onto a paper napkin, and the first Xtreme Cube was developed.

2013

In October, Xtreme Manufacturing became the majority shareholder in Snorkel, a global aerial work platform manufacturer, with manufacturing facilities in the US, UK and New Zealand as well as a global sales and distribution network.

2014

Xtreme launched North America’s largest capacity telehandler, the XR7038, specifically built to work in the oil and gas, and mining sectors. The lift weighs 115,000 lbs. (52,160kg), and has a maximum lift height of up to 38 ft. 2 in. (11.63m). Originally introduced at ConExpo 2014 as the 65,000 lbs. capacity XR6538, it was later uprated to lift 70,000 lbs. (31,751.4kg) earning its new name.